Core 1

Preliminary Analysis For Technology Inclusion Into Integrated Building Design

The

Conceptual ideology behind the High Level Selection Tools.

Through the investigation of current building practices it was discovered that there did not exist any tools which would be useful in the selection of those technologies which would be most suited to integration into a building design.

The following two tables are intended to be used as a high level selection tools for the selection of renewable and passive technologies for the inclusion into those buildings design towards minimum energy use and for the elimination of those technologies deemed not viable. The conceptual ideology behind the construction of the tables is to provide knowledge and insight into the most important considerations when deciding on what technologies to include. The table has been constructed as an easily accessible information source detailing the effects of various technologies on some of the key design considerations in the construction of a minimum energy use building.

The table is designed to decrease the time required for the elimination of those technologies which are not suitable for integration into the building design. It is essential those using the tables have a good understanding of their design objectives and the criteria driving the design and construction of their building. Those using the table must have a good understanding of their financial resource, the architectural considerations pertinent to the building and the environmental design objectives for the building.

The criteria

Constructing the high level selection tables entailed a decision making process regarding the inclusion of those categories which are the most important in the design of minimum energy use buildings.

The criteria for the renewable technology selection tool were selected to allow consideration of the most important factors affecting the economic viability, the building envelope and the environmental effect of integrating the technology.

The renewable technology criteria are somewhat different to those used in the selection of passive technologies. The passive technologies as well as being economically feasible and effective towards reducing environmental damage can have a direct influence on comfort of occupants.

The first two categories selected for renewable technologies were based upon the need to consider the electric, thermal and hot water demand profile of the building and the energy supply from the technology and how this matches the demand. The ability to match supply and demand is critical and is thus included as a category for elimination of unsuitable technology. The primary function of this project was to produce an effective strategy towards designing buildings which are efficient in terms of energy use as well as in the production of heat and power, CO2 mitigation is the most important factor relating to overall minimum energy use for this project, thus the table was constructed with the inclusion of CO2 mitigation as a category The various costs such as cost savings pertinent to power and heat from the technologies must also be considered as financial incentives are in most cases extremely important. Cost uncertainty associated with technology is likely to highly influence decisions thus this is used as a category for the elimination of technology.

Description of Criteria

Occupancy and electrical demand: A key factor in the choice of technology is the ability of the technology to meet the electrical/ thermal/hot water demand profile of the building. Every building has a different demand profile, hospitals and schools for instance have very different demand profiles. It is essential to consider the demand profile of the building and the size of the demand before reviewing technology. Information pertaining to the potential of the technologies to match supply and demand is contained within the first two criteria (shown as the first two columns in the renewable selection table). The overall efficiency of the inclusion of renewable technology is strongly affected by the ability of the technology to meet the demand profiles of the building.

Security of Supply: The renewable technologies included in the table are energy producing technologies. Some of the technologies are renewable they are not as dependent on finite resources for the production of power. This means they have the potential to produce power with reduced or zero input of energy during their use phase. The effect of reduced requirement of energy from the grid and the potential of the technology to match at least part of the demand means that the inclusion of the technology can have significant effects on the security of supply of energy to the building. In some buildings such as hospitals, the electronic industry, and other industries heavily reliant on large amounts of computing power, a high security of supply is essential and thus installing renewable technologies which heighten security is an important parameter in the design of the integrated renewable technology.

Quality of resource: The resource quality used by the renewable technology such as the sun, wind and geothermal energy will strongly influence the viability of a technology. The more resource available the more energy can be captured. This will have direct affects on the economic viability of the system as well as the potential positive effects of the technology installation for the environment.

Architectural Considerations: It is vital when designing an integrated system the effects on the building envelope is considered. All renewable technologies require integration into the building envelope, thus the building must be designed to include these technologies from an early stage.

Special Considerations: There are factors which may affect the performance of the renewable technology which are as prominent as other factors such as resource potential. These may include surrounding building topography and will affect the economic and environmental viability of the technology.

Installation Cost: In most cases the inclusion of renewable technology into building design means considerable additional purchase and installation costs. The availability of financial resource for integration of renewable and passive technology at the outset must be considered. This will determine the size and type of system that can be installed, this will affect the payback period of the system. Renewable technology begins paying for itself when it is actually producing power but its inclusion will likely necessitate additional borrowing and the associated disadvantages of interest rates.

Energy Storage/Connection to the Grid: The ability of the system to match supply with demand will directly affect the requirement for energy storage and thus the overall efficiency of the system. In some cases the supply of energy from the technology may fall short of being able to meet the requirements of the building, in these cases connection to the grid or the use of traditional fuels is essential.

Cost of Power from the Technology during the use phase:

For some renewable technologies the cost of power from the technology during the use phase may be close to zero and for others the cost will be reduced considerably from the cost of power without the inclusion of the renewable technology or when compared to conventional technology. The cost of power may rise considerably in years to come from utility companies. Uncertainty surrounding the future cost of power from the grid and traditional fuels can act as a positive factor of the installation of technology.

Life cycle cost of Power: The cost of power either electrical or heat over the life time of a technology includes installation cost, purchase cost, maintenance and fuels costs. Life time electrical costs can be defined as the cost of electricity from the system in £/KWhr.year. This will be a prominent factor for determining the economic viability of the system. Life cycle cost of heat and hot water is defined in the same way.

Cost Uncertainty: Cost uncertainty can be associated with potential uncertainty regarding the performance and maintenance of the system. High levels of cost uncertainty is a very strong reason not to opt for the inclusion of a technology as both designers and those using the building are interested in estimating costs as accurately as possible. Engineers are not known for leaving uncertainly, uncertainty implies an element of risk and any project which is risky is reduced in terms of its viability.

Most systems require maintenance, each system more or less than another. It should be clear those systems requiring higher levels of maintenance shall be subject to greater online costs for power produced from the system and are thus the less viable for the inclusion into any design.

All systems

require maintenance, each system more or less than another. It should be clear

those systems requiring higher levels of maintenance shall be subject to

greater online costs for power produced from the system and are thus the less

viable for the inclusion into any design.

The strategy for using the high-level selection tool

1) It must be clear from the outset for those using this tool that it will not give a definitive solution pertaining to those technologies which should be integrated in a building. It will eliminate those technologies that do not meet the necessary parameters for the criteria within the table which the designer has been chosen based on the driver for the design of their building. It must also be stated that this is a high level selection tool and will impart knowledge and thus aid the elimination of those technology not suitable for integration.

2) The requirement for electrical energy, heating and hot water should generally be the first criteria to be reviewed. This is the essential starting point in using the renewable high level selection tool as some of the technologies such as CHP are only appropriate for a limited range of electrical and heating demand profiles.

3) Due to the broad number of categories or criteria which each technology affects differently there must be a reasoned choice of those criteria which represent the most important drivers in the construction of the building. For instance if the main goal of the building is reduced emissions then those using the table should focus on the CO2 mitigation category. Thus those technologies which have CO2 mitigation potential should not be ruled out at this stage. In other cases the organization constructing the building may be less concerned with CO2 mitigation but with the installation costs if they haves limited financial resource for the purchase/installation of technology. The choice of which criteria to review first must be derived from the philosophy which is driving the construction of the building. Thus the various categories in the table (the various columns) should be reviewed to decide which are most important in the design of the building.

4) It is entirely of the designers/engineers choosing whether or not to review all of the criteria for those technologies that are not eliminated.

Renewable Selection Tool

|

Technology |

Occupancy and Electrical Demand |

Occupancy and Heating /Cooling Demand |

Security of Electrical Supply |

Security of Heat Supply |

Quality of Re- source |

Archit- ectural Consider- ations |

Special Consideratio- ns |

Instal Cost |

Energy Storage / Grid Factors |

Cost of Power from the Technology During the Use Phase |

Cost of Heating / Cooling and Hot Water |

Lifecycle Cost of Power

|

Lifecycle Cost of Heating/ Cooling and Hot Water |

CO2

mitigation |

Cost Un – certainty (Including

Maintainanence) |

|

BIPV |

|

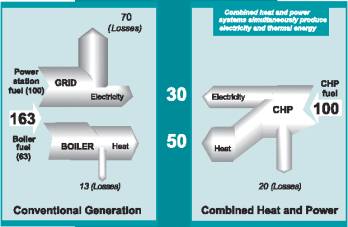

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wind Power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat Pumps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CHP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Solar Collector |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Biomass ( focus on wood fuel) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Small- Scale Hydro |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel Cells |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Integration of PV façade into a building design could be an effective method towards meeting some of this electrical demand of a building. For a very low electrical demand an appropriate selection from the huge choice of PV cells currently available could be made which could match a proportion if not the whole of the electrical demand for the building. For buildings with fairly large demand profiles it may not be possible for the installation of PV’s to meet the whole electrical demand. A system should be designed so that the supply is matched as close as possible to the demand. This will have direct effects on the necessity for Balance Of System components such as battery’s and inverters and will increase the overall efficiency of the system. It is a good design philosophy to match the time of day, month and season where peak electrical demand matches the peak electrical supply of the building. An understanding of the occupancy regimes throughout the year and thus the electrical demand profile it critical. A university buildings demand profile will be subject to sizable seasonal variations; where as the electrical demand for an office is not subject to such extreme variation. Understanding the demand profile is essential. Analysis tools such as Merit are used to make an accurate analysis of the ability of an electrical producing system to match supply and demand. If the installation of PV cells are to have significant effect on the electrical demand for the building it is probable that monocrystalline cells with efficiencies of around 10 – 15 % or polycrystalline around 10 – 12 % cells would be the reasoned choice. Thin film modules, which due to their very low real efficiencies of around 4 % have limited affect of the demand of electricity from the auxiliary supply such as from the grid. The power output of monocrystalline could be as much as 3 times that of thin film modules.

3. The security of power required for the electronics industry, industries heavily reliant on computing power or hospitals is very high. The installation of PV is an effective tool for increasing the security of supply. It is unlikely that the installation of BIPV technology itself can meet the electrical demand of most buildings but PV can go a long way to decreasing the load on the grid and thus increasing the security of supply due to factors such as the levels of uncertainty surrounding power from utility companies. In the future the security of power available from the grid may decrease as fossil fuel resources are depleted; this however is open to speculation. For some remote sites the installation of PV for the supply of the electrical load for the building could be an excellent and way of supplying electricity where security of supply is low due to a grid network which is subject to outages on a regular basis. The supply of electricity from the grid may not even be an option for some buildings; the prime example of this is the space station which is obviously not be grid connected. Thus installing PV’s can be an effective method for the supply of the electrical load in the building.

4. The inclusion of a heat recovery system shall increase the security of supply of heat in the building and reduces the requirement for an external fuel source whether that may be electricity or gas.

5. The amount of power that can be obtained from a PV façade will be greatly affected by the amount of resource that is available. The resource potential of solar irradiation is dependent mainly on the latitude and the longitude of the site. For a site in Glasgow (Scotland) for instance the amount of power that can be obtained from exactly the same PV module is a lot lower than for example in California (USA) where levels of solar irradiation are far greater. The resource potential will have significant affect on the economics of installing PV as well as the effectiveness of PV as a strategy for combating the release of CO2.

6. Architectural considerations - Flexibility of the PV system lies in the ability to choose the orientation, the tilt and the angle of the PV façade. Orientation and tilt angle play important roles in the determination of the economic viability of BIPV as well as the energy savings and thus CO2 mitigation and other environmental life cycle costing. Orientation – In the northern hemisphere a true south facing façade produces maximum power on a yearly basis. An east west orientation can produce around 60% of the power of an optimally inclined south orientation. The availability of a south facing area is a critical design factor. For an orientation which is east/west the majority of the power is produced during the first few and last few hours of sunlight. Tilt Angle -The tilt angle of a PV façade which produces the maximum amount of electrical energy is that which is perpendicular to the suns rays. For northern latitude countries it is generally accepted that BIPV orientated true south and tilted at the angle equivalent to the site latitude produce the maximum amount of energy on a yearly basis. The aesthetic value of the building can be increased though the installation of a PV façade, this is of course open to opinion. PV’s modules if integrated from an early stage in the design process certainly have potential to increase the look of a technological advanced building.

7. Special Considerations – It is essential when considering the installation of a PV system due care is taken to include the surrounding building topology which may cause shading of a BIPV system and reduce its economic and environmental viability. It should also be noted that for a PV panel or module the cell subject to the lowest level of irradiation determines the output of the whole module.

8. The installation of BIPV is likely to be more expensive than traditional cladding or glazing materials. The larger the area of PV coverage the larger the cost. In the section on further analysis there is some indication of the installation cost of various types of PV. High efficiency mono-crystalline is generally more expensive per m2 than polycrystalline or the thin film technologies. The available resource for the inclusion of BIPV plays an important role in choosing the type of PV. Monocrystalline PV is the most expensive PV types to cover a specific area of façade, polycrystalline is slightly cheaper and thin film PV types are considerably cheaper again.

9. It is unlikely that the electrical demand can be matched from a PV facade alone unless the electrical demand for the building is low; connection to the grid in most cases essential. In some countries, such the US, the grid can act as a storage device with excess electricity being sold back to the grid when not required and taken from the grid when necessary. In the UK this is not currently an effective financial strategy as the sale price of electricity back to the grid is many times lower than the cost of electricity from the grid. UK grid connection legislation can make this very difficult. In the UK there is also legislation which states that only one supply is allowed for supply of building with small electrical loads. Hybrid systems have both battery and grid connections. Battery backup may facilitate cost savings if power is not required from the grid during peak hours. The following considerations are important for efficient electrical storage from a BIPV A>Access the duration when the backup system is expected to provide power when the electrical demand is not matched by the supply from the BIPV B >Multiply the time period by the daily power requirement C>Add a safety factor to the battery sizing equation for the depth of charge. This is to avoid over draining of the battery. (It should be noted that batteries do not like to be discharged and battery lifetime is reduced the more frequently the battery is drained. As the power output from the BIPV system is DC and most appliances within the building require AC an inverter is required to convert DC to AC. The shorter the lifetime of the battery the greater the environmental cost of the use of battery’s as a backup). Where export of electrical energy to the grid is not possible, a good philosophy to extend battery life is to maintain maximum charge of the battery by charging the battery either from the grid or directly from the BIPV or from the grid.

10. Cost

of electricity from the grid. The cost of electricity during the use phase is

near to zero, maintenance costs will certainly play a role in the cost of power

from PV installation during its use phase. Maintenance costs for thin film

cells are likely to be considerably higher than for monocrystalline or

polycrystalline cells as they suffer from considerably higher amounts of

degradation. Monocrystalline cells which have efficiencies of around 11 – 15 %

and will undoubtedly produce the largest amount of power. Thus the installation

of monocrystalline PV cells will result in the biggest cost saving with respect

to the need to purchase electricity to compensate for the deficit of the

electrical demand of the building.

12. Life

cycle cost of electricity. The primary factors affecting cost of power derived

from BIPV systems are the installation cost of the system and maintenance of

the system. The cost of paying back the BIPV is calculated on a yearly basis

can be divided by the amount of energy which is captured by the system over the

period of one year. This will give the life cycle cost of electricity from the

system in £/KWhr.elec.year. This can then be used as a factor for determining

the economic viability if the system. The availability of government or other

subsidies for the purchase and the installation of PV cells will also play a

significant part in the determination of the life time cost of electricity. The

resource potential will have direct affects on this cost for the same modules.

Different systems will also be subject to different costs. The cost of

electricity in £/KWhr will likely be at least several times more expensive than

electricity from the grid. The cost of electricity from a PV array will

undoubtedly not match the cost of electricity derived from the grid for at least

10 years. However the cost of PV’s is dropping and as technology advances the

efficiency of PV cells increase thus the cost of PV derived electricity is

falling. The availability of government subsidy is an essential feature of

decreasing the cost of electricity from PV, and indeed will act as a strong

incentive for the installation of PV façade. Refer to http://www.pv-uk.org.uk/uk/index.html,

http://www.est.org.uk/solar/,

14.

Integration of PV technology into a building will result in mitigation of the

emission of CO2, the levels of CO2 mitigation is

dependent on factors such type of PV, site, supply demand matching, and overall

system efficiency. Each case must be evaluated on its own merits and downfalls.

15. Cost

Uncertainty for PV’s: The level of cost uncertainty associated with PV is

strongly related to the type of PV cell. It is likely that the levels of

uncertainty of thin film cells will be higher than for monocrystalline cells.

This is due to the possibility of the oxidization and degradation of thin film

cells from sunlight and other environmental conditions such as wind and rain. Thin film cells such as the most common type

of cell a-Si tend to suffer from reliability problems more so than mono or

polycrystalline cells. It is obvious that when considering spending perhaps two

or three times more on a façade which produces electricity which is driven by

environmental factors such as mitigation against the release of CO2

that there is a high level of confidence in the installation of PV modules.

16. Wind

turbines, electrical demand profile: It is important to consider the electrical

demand profile of the building and how this can be matched against the supply

profile from the technology. For university buildings the demand varies

throughout the year with increases in demand during exam periods and in the

winter generally when more electrical energy is used to power lights and

electric heaters. This matches well with the supply profile from wind turbines

in Scotland, where most of the wind energy is captured during the winter period

when the wind speeds are higher. In other part of the world wind speeds may be

constant all year round or may be greater in the summer period. Positioning of

wind turbines on a building should be matched with the time of day, month and season where peak electrical demand matches

the peak electrical supply of the building.

18. The

security of supply of electricity will be increased by the inclusion of wind

turbines integrated into a building design. If security of supply is a key

component of the building concept then this is a good incentive for the

installation of wind turbines.

19. NA

20.

Without sufficient resource the installation of wind turbines is likely to be a

very much ineffective. It is essential to conduct a resource analysis. The wind

speeds surrounding buildings are generally much lower than in land with a much

flatter topology. The amount of energy that can be captured in some cities and

town though out the world may justify the selection of wind turbines and in

other town the wind speed may be so insignificant to eliminate wind turbines as

a valid and economically and environmentally viable option. For ducted wind

turbines it is estimated that the turbine does not start operating outside of

wind speeds which are around 5m/s. Thus some analysis whether wind speeds are

higher or equal to this value during a substantial proportion of the year is

necessary.

21.

Integrating wind turbines into the building design is essential as the amount

of energy that can be derived is directly related to the fluid flow

characteristics which are affected strongly by factors such as surface angles

and building height. It is likely that most integrated wind turbines would be

of the ducted type as other type of wind turbines will significantly effect the

over all appearance of a building. The installation of larger turbines would

undoubtedly be even less cost effective in the built environment as wind speeds

are very much less than conditions which would provide sufficient incentive for

the installation of wind turbines as an economic and cost effective electricity

generation scheme.

22. The

surrounding building topology will be a one of the most important

considerations in the analysis of wind speed. It is essential than there is a

knowledge of the surrounding building topology and any likely changes in the

future are investigated which may affect wind speed profiles in the surrounding

area.

23. The

Installation cost of wind turbines is likely to be quite high. Currently it is

very difficult to put any accurate cost on DWT’s as they are not as of yet

being manufactured.

24. The

amount of energy which can be derived from ducted wind turbines is likely lower

to be lower than that of BIPV although this is obviously dependent on the

resource potential of the site and the amount of ducted turbines integrated into

the building. Generally however the building will require grid connection and

battery storage. For other relevant points refer to point 9

25. During

the use phase of wind turbines the cost of electrical power will be minimal and

only maintenance costs should be a factor

26. NA

27. The

life cycle cost of electricity will be dependent on a number of factors such as

the amount of resource as well as installation cost and maintenance. It is likely

that the cost per KWhr from ducted wind turbines will be comparable with that

of PV’s. For relevant information refer to point 12

28. NA

29.

Integrating ducted wind turbines into a building should result in CO2

mitigation but this is very much affected by resource and the manufacturing

process. It is critical an analysis of the resource potential at site is

carried out in order to decide upon the effectiveness of the installation of

ducted wind turbines.

30. Cost uncertainty associated with wind turbines is a considerable. This is mostly related to ducted wind turbines being a new technology. The amount of energy which can be captured by the wind turbines is subject to a degree of inaccuracy as the technology is in its infancy. The potential for change in surrounding building topology and thus a possible reduction in the wind speed which will affect the fluid flow characteristics through the turbine adds cost uncertainty to the installation. There is also uncertainty over the amount of and cost of maintenance that is likely to be required from the turbine.

31. NA

32. It is important that a profile of the space heating and hot water demand is created before GHP can be analyzed as a strategy towards meeting these demands. In many cases a GHP system is oversized, this means increased life time cost of energy derived from the grid. The demand for space heating and hot water should be able to be matched in most cases with the installation of a GHP system. Those building which employ high degrees of passive technology are likely to be subject to lower heating requirements. The effectiveness of installation of GHP systems for small heating demand such as from residential or commercial applications is open to question and the installation of such a system will need careful analysis.

33. NA

34. Security of heat/hot water supply. Installation of heat pumps such as geothermal heat pumps into a building design will most likely increase the security of supply of heat to a building. Less energy to produce the same amount of heat. The GHP system is a very reliable as long as the appropriate maintenance such as cleaning the heat exchanger and changing filters is carried out periodically. GHP system components are often housed inside with the piping underground thus protecting these system components from a potentially hazardous environment.

35.

Quality of resource: The amount of energy that will be saved over the course of

a year is related to the quality and access to sufficient resource. Energy and

cost payback will be affected considerably by the resource. A large amount of

sites will require drilling and installation of a piping system underground. AT

some sites where there are disused mines for example the resource will be more

valuable than normal underground installations.

36. GHP

systems have the potential to be integrated into the building design without

the need for any major influence upon the building envelope generally

eliminating the requirement for convention HVAC equipment to be installed in

the plant room of a building. Thus GHP systems have the potential to be more

architecturally pleasing than their counter parts.

37.

Underground mines for instance are a special consideration when considering the

installation of GHP. The resource available at these sites situations could

potentially make a GHP a viable both economically and environmentally. For

residential applications (especially new buildings) it is likely that

horizontally installed installation would be the most cost effective. For

commercial application it is probable that vertically installed pipe work is

necessary as a greater amount of land would be necessary in order for the GHP

system to supply the required duty. Vertical systems also cause reduced

disturbance to the existing landscape. Sites with the availability of a lake or

perhaps a pond may well benefit from the use of this resource as the medium

from which to absorb heat. This will most likely be the lowest cost option as

drilling costs can be negated to some degree.

38. Installing a GHP is a costly exercise. A significant proportion of the cost of installing a GHP system is the drilling costs. Other costs include piping, compressor and a heat exchanger costs. At some sites the installation of a GHP would not be practical, such as a highly urbanized city centre where drilling and installation may be disruptive to an existing building without prior consideration for the installation of a GHP. For GHP systems to be economically feasible the system and piping must be designed before the construction of the building begins.

39.

Geothermal heat pumps are used as an efficient way of supplying space

conditioning, a GHP system must also be connect to the grid as the electrical

energy is required to operate the compressor and the pump.

40. Generally installation of a GHP will result in cost savings from reduced electricity demand or from fuel demand for space heating. GHP can also be used for air conditioning (cooling) without any difficult changes to the system. However the decision of whether or not to install a heat pump must be related directly to the building space heating and hot water demand. In cases where the heating demand is very low the installation of a GHP is likely to be an ineffective economic strategy towards reduced cost and environmental benefits. In commercial buildings the installation of a GHP is considered to be highly competitive when compared to standard cooling towers or boiler, and have lower energy and maintenance costs. For some of the potential energy savings that can result from the installation of GHP systems the following web page is a good guide. http://www.eere.energy.gov.erec/factsheet/geo_heatpumps.html

41. Not

including the cost of installation of the system, the cost of heat during the

use phase of a GHP should be substantially less than for an equivalent HVAC system

or from electrical heating systems. GHP generally use around 25-50% less

electricity than conventional heating and cooling systems.

42. The cost of electricity is also likely to be reduced although this would be very much dependent on comparison of electrical costs for an alternative system which uses some degree of electrical heating for the space heating and/or for air conditioning. In situation where a GHP is compared to a standard air conditioning system the savings should be substantial.

43. Any

building with a substantial heating or cooling demand should benefit from the

installation of a GHP with cost payback periods around 5 to 10 years. After the

payback period is complete the savings in fuel would be substantial. The exact

cost savings from the installation of a geothermal heat pump are difficult to

quantify as they are dependent of the fuel types, fuel mix and technology they

are substituted for.

44. It is

likely that the installation of geothermal heat pumps will result in significant

reduction of emission of CO2 for a medium to low demand for space

heating or hot water requirement. GHP systems are often as much as 70% more

efficient than its HVAC counterparts. It

is estimated that the installation of 2,000,000 heat pumps by the year 2005

just within the US would save around 1.2 million metric tons of carbon per

year. CO2 savings will however be dependent on the amount of

excavation work that is necessary for installing the system. For closed loop

GHP systems placed in ponds, CO2 emission savings will likely be

even higher than for underground installed pipe work.

45. The maintenance costs of GHP systems should be a lot less than for a standard HVAC system. It is however essential that the appropriate maintenance is carried out periodically, maintenance tasks include the cleaning of heat exchangers in order for effective heat transfer coefficients, lack of maintenance could cause the system to fail. It is also important that is a good understanding of the system in order that the necessary maintenance can be carried out. There is likely to be more cost uncertainty about the costs involved in the installation of a GHP system that a standard HVAC system due to drilling costs. However it should be said that GHP is in no way a technology in its infancy and there are many thousands of systems installed thought the world which are both economically beneficial as a solution to the mitigation of CO2 for the production of the same amount of energy. It is estimated that the maintenance cost of a GHP system could be as low as 30% of a conventional heating and cooling system.

46. Modern

CHP technology is available at around 15KWe,

any buildings or applications with an electrical demand of less than this value

are likely to be an ineffective environmental and economic strategy. For CHP

systems with an electrical demand of less than 100KW the economics will need

careful analysis. In order for a CHP system to be successful it is essential

that there is a stable and continuous electrical demand for substantial proportions

of the year. Businesses which have continuous electrical and heating demand

greater than 100KW are prime candidates for the inclusion of a CHP system. The

main non-industrial applications where CHP has proved to be effective are in

hospitals, hotels and leisure centers. Around 90% of installed CHP systems are

in energy intensive applications.

47. CHP

units are sized based upon the heating demand rather than the electrical

demand. A substantial and consistent heat demand is generally regarded as a fundamental

requirement for CHP to be economically effective. Most sites using CHP have a

heat to power ratio of approximately 2.3:1, this ratio is generally pertinent

to larger systems of perhaps 100KW. On the smaller demand side gas fired

reciprocating units give a heat to power ratio of around 2:1 while gas turbines

give ratios of around 3.7:1. CHP is often used to provide the base load for the

heating requirements with a standard HVAC system used as the backup. It should

be said however that an exact match on the heating demand is not

essential. An understanding of the

heating and electrical demand is absolutely essential before a CHP system can

be evaluated.

48. The security of supply of electricity for those buildings which have demand profiles suited to CHP should be increased due to the reduction on the overall requirement for fuel to produce the same amount of energy. A building employing CHP will have reduced reliance on utility companies or from the grid for the supply of electrical energy. For some sites there may be regular outages and thus the security of supply of electricity is likely to be quite low. This would maybe applicable for remote hotels or large residences. It is essential however that a secure supply of the fuel/prime mover used for the generating unit or the engine is available otherwise installing CHP would be hazardous and could decrease the security of supply. Thus an analysis of the supply network of the fuel used in the CHP unit is necessary.

49. The security of the supply of heat will be increased again in the presumption that the security of supply of the prime mover is greater or equal to the supply of electricity. It should also be stated that if the CHP unit is used as a base load unit then this will have a direct positive effect on the security of supply as the demand is being matched mainly by the CHP system and augmented with standard HVAC equipment. Maintenance factors will also have a direct effect on the security of supply. As CHP systems is required to be run at maximum load for as much time as is possible it is essential to carry out the appropriate maintenance to avoid frequent brake downs and thus intermittency of supply.

50. The quality, security and cost of fuel supply for a CHP unit will drive the economic cost savings as well as the environmental benefits. It should be stated that CHP technology is not an entirely renewable technology and it depletes the resource reserves of the fuel acting as the prime mover. If the system has been properly sized as is operating effectively it will certainly result in considerable fuel saving.

51. The

effect of a CHP system on the architecture or the aesthetics of a building is

likely to be fairly limited. The main considerations with regard to the

building envelope are for the inclusion of a space for the CHP system.

52. NA.

53. The installation of a CHP unit is likely to be more expensive than standard HVAC equipment. However there may be scope for savings when compared to the installation of both electricity producing technology and heat or hot water supply systems.

54. Although CHP systems are generally designed to supply the base load for the electrical and heating demands of a building in virtually all cases grid connection as a backup is necessary for supply of the electrical demand base load in the event of the CHP system failing as well as a electrical top up or auxiliary. The backup equipment supplying space heating or hot water may also be based on electrical input thus grid connection is inevitable for most buildings.

55. The

cost of energy during the use phase of CHP should be substantially less than

the cost of fuel or electricity for two separate systems to supply the same

amount of energy. Again this will only apply in cases were the CHP system is

effective and has been properly sized for the application.

56. The

cost of heat form a CHP system should be considerably less than the cost of

heat from a traditional HVAC system. CHP, if effectively sized should be an

effective strategy towards reducing total fuel bills.

57.

Including the installation costs and possible disposal costs as well as

maintenance costs the life time cost in £/KW.hr should be far less than using

energy from the grid, there is a certain level of uncertainty about the cost of

electricity form the grid, however it almost likely the cost of electricity

will rise substantially in future years.

58. The

lifetime costs of fuel should be far less than the costs associated with a

standard HVAC system for the same space heating and hot water demands. See

above

59. CHP is

generally regarded as one of the most effective tools to combat the release of

CO2 into the environment. This is because the efficiency of power

from a traditional power station for a coal-fired installation is likely to be

around 35%. The losses of power from

transmission, distribution are estimated as high as 70% with a further 13%

losses in a traditional boiler for the production of space heating. Thus as

power and heat is produced at the point of demand then a very large proportion

of these losses can be mitigated through the use of CHP. CO2

mitigation will be dependent strongly on the generation of power from other

sources to supply the heating and electrical demand for the building. The following web site www.energy.rochester.edu.uk/est/chp2002.html

gives an indication of the potential for CO2 savings based upon different

scenarios which differ in the mix of fuels and the generation technologies for

the production of electricity, space heating and hot water.

60. The level of cost uncertainty associated with CHP technology is fairly low and not much greater than for standard HVAC equipment. The installation of a CHP unit can have a positive influence on the uncertainty associated with energy from the grid.

61. NA

62. Solar

collectors are used for either hot water or for space heating. There must be

sufficient demand to warrant the installation of solar collectors. However for

most buildings either residential or commercial solar collectors will be unable

to meet the demand for the space-heating load. This is especially true for

northern latitude countries or those buildings sited in temperate regions.

Solar water heaters are generally used to supply the hot water demand. In many

cases the demand for hot water will be greater than the optimal area used for

supply of hot water from the solar collectors. Solar collectors are especially

effective in warmer climates such as Brisbane or Sydney (Australia). It is essential an approximate demand for

hot water hot water is known before a further investigation into the

installation of solar collectors. One of the main drawbacks of the installation

of solar collectors in northern latitude countries is higher amounts of solar

isolation during the summer periods when the water heating requirements are

lower. This generally means there is a significant deficit in the amount energy

required for water heating in the winter, thus traditional water heating

equipment is necessary. In domestic applications it is estimated that

approximately 10 to 15 sq feet of solar collector is necessary for each member

of the household. A storage tank of around 20 to 30 gallons per person may be required.

The system should be designed so that the collectors are optimally inclined

when at the point when maximum demand on either hot water or space heating is

required. In the description of

solar collects an explanation of commercial and industrial design

considerations is given.

63. NA

64. The

security of both hot water and space heating will undoubtedly be enhanced

through the inclusion of solar collectors. In most applications the system will

be sized not for meeting the demand of hot water and space heating throughout

the year but for the peak periods when the incident solar radiation is at a

maximum, the installation of solar collects will mean reduced reliance on

either HVAC equipment or electrical water heating equipment. It will also mean

reduced reliance on non-renewable resource which will enhance overall security.

65. The

quality of resource will strongly affect the economic viability and

environmental effects of the installation of a solar water heating system.

However it is likely that although cost savings are higher for sites where

there is a higher degree of solar radiation, solar collectors should be

economically viable for most sites as well as being an environmentally positive

solution to reduced CO2. In the UK around 75% of the solar energy is

received during the months April to September and around 25% during June and

July.

66.

Installation of solar water heaters is likely to require some consideration

during the design of the building envelope. The amount of resource that is

available is dependent of the orientation of the solar collectors as well as

the angle of installation. Thus it is necessary to simulate the supply of hot

water from different areas and types of solar collector. For hot water

applications the solar collector will most likely be positioned at an angle of

around 30 degrees south, although small changes in the orientation and angle

will not affect performance of the system considerably. Most systems will require

a storage tank of significant capacity, thus the building must be designed for

the inclusion of a space for the storage tank. In situations where it is

necessary to use a closed loop system it is necessary to use a drainback

tank/heat exchanger tank, for most applications this needs to be placed below

the solar collector.

67. One of the special considerations when designing a solar collector is to analyze the surrounding building topography which could cause shading to the system and thus result in a reduction in the overall system efficiency and thus the systems environment and economic viability.

68. The

initial installation cost of a solar collector system is high. For domestic

systems installation costs can range from around £1000 to £3000. It should be

noted that the installation cost will be highly dependent on the size of the

system installed and the availability of subsidies (any subsidies worth

mentioning) For commercial and industrial applications the cost of a solar

water heating system is likely to be far greater.

69. An

essential part of the solar water heating system and active solar space heating

is the requirement for considerable storage of hot water. For almost all

applications a back up water heater is necessary.

70. The

cost of electricity during the use phase will be reduced if the system is

partly replacing a heating system which previously used electrical equipment

for some or all of the heating demand. The installation of a solar collector

system for either hot water or for space heating will generally require a

backup system, this may be electrical.

71. The

cost of heating during the use phase of a solar water heating system or a

active space heating system should be much reduced from the cost from a

standard hot water boiler or HAVC equipment. The actual cost again will be

highly dependent on the size of the system. The ratio of hot water for instance

that can be achieved from well designed system can as much as 90% in regions

such as northern Australia and parts of the US such as California and will

likely be around no more than 50% for countries such as Scotland. It is

interesting to note that the financial saving in water heating is fairly

consistent over the whole of Australia as the amount of energy which needs to

be supplied in northern Australia is a lot less as the water temperature tend

to be much hotter than in southern Australia, thus the energy supplied in the

southern states is actually more valuable than in the northern states. This

scenario can be applied in many places throughout the world.

72. The

cost of an equivalent non solar water or passive heating system should be

deducted from the cost of a solar heating system in order to clarify the

economic feasibility of the inclusion of a solar water or heating system into a

building design. Cost payback can vary substantially and will be related to the

resource available, subsidies, and how well the supply from the system can meet

the demand profile. Payback periods can vary from around 4 year to greater than

10 years.

73. The

life cycle cost payback for a hot water system is highly depended on the fuel

types the solar collector system is partially replacing as well as the other

factors already considered in point 72.

74. The

potential environmental benefits of the installation of a solar water heating

system can be substantial. In some cases CO2 mitigations can be as high as 75%

over the lifetime of the system. It must be noted that solar water heating may

not always be environmentally friendly; this is highly dependent on the type of

boosting that is used for heating water. A system with an electric booster may

actually be responsible for the production of more CO2 than an efficient gas

only water heater in colder climates where the system is more reliant on

boosting from than in hotter climates. It is important to note that if main gas

is available this should be used as the booting fuel for maximum CO2

mitigation.

75. The level of cost uncertainty associated with solar water heating and solar space heating is fairly low. The technologies used are well established. The maintenance of the systems should be minimal and a contract which includes installation as well as the purchase of the system will help to eliminate any potential for problems with the system.

76. Biomass

has the potential to be integrated with other technologies such as CHP where

electricity is produced along side heat. In locations where electricity is

produced either to supply the base load or as a back up from either engines or

generators it is possible to consider the use of biomass as the primary fuel

supply for the CHP unit. The combination of biomass and CHP has the potential

to be an effective strategy for significant abatement of emissions such as CO2.

However in most cases and especially where CHP is not a practical, biomass will

be used as a technology mainly for the production of heat only. There is also

some significant complexity surround the use of biomass as a fuel in both

engines and generators where fuels such as gas and oil are normally used.

77. It is likely that the installation of a boiler capable of converting biomass to useful energy would only be appropriate where the heating demand for the building was fairly substantial. Minimum heating loads of around 5 – 10 KWhr are essential for the installation of log boilers. Wood chip boiler and pellet burning boilers could be economic at slightly lower values but the economics of installation of boilers of this size is likely to be uncertain and warrant careful consideration. For building with a space heating demand greater than 100KWhr the economics could be very promising. For buildings with variable demands such as those associated with high levels of passive heating and cooling, for example those buildings situated in colder climates such as those in the northern latitude countries, would probably be better suited to a chipped fuel boiler or a pellet fuel boiler; as they are more versatile and can maintain efficient and clean burning more easily when subject to loads which are perhaps as low as 30% of the maximum continuous rating for the boiler. For more information refer to http://www.dti.gov.uk/NewReview/nr48/html/in_business.htm

78. The

security of supply of electricity for most buildings is not likely to be

increased through the inclusion of biomass for the production of electricity.

In those cases where CHP is practical there may be some security benefit from

the use of biomass although those benefits are difficult to quantify.

79. The security of heat supply could in some respects be increased through the installation of a wood fuel boiler as doing so reduces the reliance on fossil fuels such as heating oil, LPG or natural gas. For some buildings the security of supply of fossil fuels may be lower than for other types of biomass such as wood chips. This is more likely in remote areas. The installation of a wood fuel boiler would in most cases decrease the security of supply of space heating within a building due to the levels of uncertainty associated with the supply of the wood fuel due to the relatively small size and instability of the market in comparison to that of fossil fuels. In the urban environment it is likely that the supply of wood fuels are less secure than for traditional fossil fuels.

80. The quality of fuel is an important factor affecting the inclusion of a biomass boiler. To use the example of wood fuel, of the three main types of fuel available pellets are by far the most versatile fuel, as well as the most expensive. In the UK there are only four major sites manufacturing this fuel. The quality of the fuel has significant effects on the energy contained with the fuel, thus the economic viability is affected by the type of fuel. Lower grade fuels will likely cause increased difficulty in maintenance of the boiler and will result in reduced efficiencies. Reduction in efficiency shall result in a decrease in the environmental positive aspects of biomass. This is true for most systems subject to variation in quality of fuel. However the quality of biomass fuel is extremely varied and requires careful analysis.

81.

Architectural consideration of biomass. There are no real special

considerations necessary for the inclusion of a biomass boiler with a building.

The main consideration is the necessity for a boiler room as well as the

necessary piping for space heating and hot water demand.

82. The

main special consideration is the distance form the supply of fuel as well as

the strength of the market for the supply of the fuel. It is vital that there

is a secure network of supply. The type of transportation used for the supply

of the biomass fuel will play a strong role in the environmental impact of

using biomass as a fuel. The larger the distance for the transportation of fuel

the greater the uncertainty regarding mitigation of CO2 when

compared to other fuel types. It has

been proposed that a supply network within a radius of around 30 miles is

necessary for biomass to act as a positive solution to CO2

mitigation; however this is very much an approximate figure and will depend

strongly on the transportation methods used.

83.

According to the DTI it is estimated that a wood fueled heating has the lowest

capital expenditure of all the renewable energy technologies. It is suggested

that the cost of installation of a wood fuel boiler should be around £150 to

£250/KW of installed capacity. This is as much as 10 times lower than other

renewable technologies. Wood fueled boilers are likely to be more expensive

than conventional HVAC technology. In the UK is (at the time of publishing)

there is little in the way of subsides awarded for the installation of biomass

boilers. In other European countries there are subsidies which mean a

significant reduction in the purchase and installation of biomass boilers, thus

making biomass systems more economically viable.

84.

Grid/Storage factors. In most cases a biomass boiler would provide the base

load for the supply of space heating within a building. It would be necessary

to maintain grid connection to maintain security of supply as biomass supply

markets are relatively unstable within the UK. It will also be necessary to

provide storage space for the fairly large amounts of fuel. It may also be

necessary for buildings employing the use of biomass as the base load unit to

install a backup gas boiler for peak periods of heating requirement or to

maintain the required comfort conditions on extra cold days. In installing a

backup gas boiler there will be significant added installation and purchase

costs.

85. NA

86. Cost

of heat during use. Running costs of around 1.0p – 1.5p/KWhr have been

suggested which are actually cheaper than electricity, heating oil, LPG and

only slightly more expensive than mains gas. The cost of biomass is kept low as

most fuel such as wood as currently exempt from the climate change levy.

87. NA

88. The lifetime cost of heat form a biomass

source is likely to be difficult to quantify due to the uncertainty surrounding the lack of a secure supply market. With an increase in

the security of the biomass market the life time cost of wood fuels could be lower than that of heating oil, LPG and electricity. The distance

to supply of biomass is perhaps the most important factor affecting the lifetime economic viability of biomass. One of the most significant developments

in the biomass market is some innovative thinking from “Torren Energy” located in Glencoe. Torren energy installs biomass boilers free of charge and do

not charge for the delivery of fuel but for hot water use. Innovative marketing strategies such as this could facilitate the expansion of the biomass industry. The cost uncertainty surrounding the requirement for a quality, readily available and local fuel supply is reduced to near zero as there is no initial outlay for the installation of the biomass boiler. If Toreen Energy were to fold then the cost penalty paid from those companies employing their boilers for space heating and hot water use would be small. If many companies were to employ this type of supplier customer relationship the expansion of the biomass market would be very likely indeed. Although the onus is entirely with the company employing this marketing strategy to stay afloat in doing so the owners of the building using the biomass boilers would be very much interested in the success of the fuel supply company.

89. Biomass has the potential to play

a significant role in the mitigation of CO2 production. Biomass is neutral in terms of the carbon cycle it has the potential

to emit far less carbon than its rivals such as electricity, fuel oil or LPG. One of the main downfalls of biomass as a fuel

is the necessity that it is transported from fairly remote locations. For every mile of transportation there is an associated

emission of CO2, thus the distance of transportation as well as the efficiency of the transportation system plays a vital role

in determining just how effective biomass is as an alternative fuel which can supply the space heating demand for large residential,

commercial or industrial applications. Refer to 82.

90. Cost

uncertainty associated with the use of biomass boilers to supply the space

heating demand of large residential, commercial or large industrial facilities

is high. This is due to the reliance on a fuel which is derived from what is

presently a fairly unstable market. It is critical to conduct significant

analysis of market trends of biomass in the surrounding area to ensure

confidence in a reliable source of quality fuel.

91. The requirement for electrical energy for

buildings situated close to a river will be the main driving force behind the construction of a small scale hydro facility. In some locations

there may be difficulty with the supply of electricity due to large distances between the population and the main distribution network.

Small scale hydro is only suited to these sites where there is suitable resource. In comparison to the other renewable technologies for the

production of power small scale hydro is a technology which is generally not suited to the supply of individual residences or small commercial

sites. The three types of small scale hydro are defined as micro; which are less than 100KWe typically for the supply of a few house or a small

factory. Mini – typically for the supply of a small community or medium sized factory. Small – typically 1MWe to 10MWe for supply of the regional

or provincial grid. A facility with a capacity of around 1MWe would be sufficient to supply the electrical demand for around 550 houses.

This is assuming that the site is able to generate around 65% of its capacity over on a yearly basis. It is indeed highly probable that a town of

around 1000 people or substantial industry such as steel manufacture of distilleries would warrant construction. Within the UK a small facility

would be around 5MW of installed capacity thus a demand represent a sufficient percentage of this would be necessary to warrant further investigation.

Facilities with a capacity of around 100KW are possible but less common.

92. The output from

small scale hydro is of course electrical energy. It is possible to use electrical power to supply the

space heating and hot water demand. If the supply of fuels such as heating oil or LPG is unreliable for

remote locations the electrical energy generated from the facility may well be suited partly for supply

of some of the heating demand as well as the hot water demand.

93. Installation of small scale hydro facility will

certainly dramatically increase the security of supply of electricity to the surrounding area/built environment. Small scale hydro is widely

regarded as a reliable technology and is unlikely to suffer from failure. For remote towns the security of supply of electricity may be much

lower than for city locations. Harsh environmental conditions may regularly cause disturbance in the supply of power. The installation of

small scale hydro will reduce the associated problems of reliance on a distribution network with is subject to regular failure.

94. The

security of supply of space heating and hot water would certainly increase for

similar reasons to that of electrical power. The supply of heating oil and

other fuels may be problematic and if affected by environmental conditions such

as snowfall in the winter small-scale hydro would certainly increase security.

95. Consideration of small scale hydro is of course only

relevant for those situations where there is a resource which is suitable for the installation of a small scale hydro facility. Installation of

small scale hydro will have significant effects on the surrounding terrestrial habitat; areas which have an especially fragile ecosystem are

unlikely to be consideration for a small scale hydro facility.

96. Installation of small scale hydro will have significant

effects on the surrounding terrestrial habitat; areas which have an especially fragile ecosystem are unlikely to be consideration for a small

scale hydro facility. Installing a small scale hydro facility may mean diverting the water course and may have a positive or negative effect on

drinking water supplies for the local population as well as for surrounding agriculture and thus crop yields and local income.

97.

Surrounding terrestrial habitats and rare species.

98.

Installing a micro hydro facility is likely to be in excess of £100,000 for a

capacity of around 16,00KWe. However it is impossible to generalize the cost of

small, micro or mini scale hydro as construction costs are dependent on many

external factors such as the availability of the construction materials and the

cost of labor. Installing a small-scale hydro facility is a significant civil

engineering exercise and will require a very large initial investment. Costs

running into millions are not unlikely. It is probable in most cases that small

residential commmunties or businesses will be unable to afford the significant

initial expenditure. Government grants, loans from the World Bank or

international aid agency for poorer countries are the sort of necessary

financial backup required.

99. Once in use a

small hydro facility should have very minimum power costs. The main running costs will be maintenance

and labor and will depend on the size of the facility.

100. Once

in use a small hydro facility should have very minimum power costs, there will

be some maintenance associated costs.

101. See

above

102. The cost of heat produced from electrical HVAC equipment

is often greater than for efficient boilers using LPG, heating oil or natural gas.

Thus the lifetime cost of producing heat with electrical equipment supplied from a

hydro facility would likely be less competitive than it counterparts. Much is dependent

on the difficulty and cost of transportation of traditional fuels,

it likely the competitiveness of heating with electricity supplied from

small scale hydro will be increased for those sites which are very remote

103. CO2 mitigation.

The emissions during the use phase of a small scale hydro facility are likely to be negligible

in comparison to those emissions associated with traditional production of electricity from coal,

oil or gas. There has been much talk in recent years that large scale hydro facilities may release

large amounts of CO2 resultant from decaying biomass. Small scale hydro facilities are unlikely to

sufferer from the same problems as the body of water which is dammed is very much smaller than that

of a large scale reserve, thus emissions from decaying biomass are very low. The body of water is also not stagnant.

The main body of emissions is a result during of the construction phase of the components which make up a hydro facility

such as the feeder canal. It may also be necessary to construct access roads which will contribute a significant amount of

emissions. Steel and concrete both of which are usually made using electricity constitute the largest fraction of the materials

used in a hydro facility. It has been estimated (ORNL/RnF (1994)) that the emissions associated with a hydro facility are twice

reduced from the emissions associated with a traditional coal fired power station with desulphurization. The site on which

construction is carried out plays a vital role in determining the amount of emissions associated with a hydro facility. For site

which can be retrofitted the emissions will be far less than for all new sites. It is impossible to quantify the savings in

emissions the production of electricity from a small scale hydro would bring. However a reduction in the emission of CO2 from

traditional electricity production should be significant considerable for most installations.

104. CO2

mitigation. The emissions during the

use phase of a small-scale hydro facility are likely to be negligible in

comparison to those emissions associated with traditional production of

electricity from coal, oil or gas. There has been much talk in recent years

that large-scale hydro facilities may release large amounts of CO2 resultant

from decaying biomass. Small-scale hydro facilities are unlikely to sufferer

from the same problems as the body of water which is dammed is very much

smaller than that of a large-scale reserve, thus emissions from decaying

biomass are very low. The main body of emissions are a result during of

construction phase of the components which make up a hydro facility such as the

feeder canal. It may also be necessary

to construct access roads which will contribute a significant amount of

emissions. Steel and concrete both of which are usually made using electricity

constitute the largest fraction of the materials used in a hydro facility. It

has been estimated (ORNL/RnF (1994)) that the emissions associated with a hydro

facility are twice reduced from the emissions associated with a traditional

coal fired power station with desulphurization. The site on which construction is carried out plays a vital role

in determining the amount of emissions associated with a hydro facility. For

site which can be retrofitted the emissions will be far less than for all new

sites. It is impossible to quantify the savings in emissions the production of

electricity from a small-scale hydro would bring. However a reduction in the

emission of CO2 from traditional electricity production should be significant

considerable for most installations.

105. Cost

uncertainty. Small-scale hydro facilities are not a new technology yet there will

be some level of uncertainty associated with deployment. The decision to

construct a hydro facility would not be taken lightly, a massive amount of

initial expenditure is required and thus those partaking in investment in such

an activity must be certain from the outset they are able to supply all

necessary revenue. It would be disastrous both environmentally and economically

were a site to end up half constructed to sufficient funds. It is vital that a

hydro facility is well maintained; in doing so large capital expenditure should

be avoided once the site is finished. Generally hydro facilities require low

levels of maintenance and are very reliable.

106.

Requirement for electrical energy must be sufficiently high to warrant the

installation of a fuel cell power plant. In recent years there has been

significant development of smaller fuels cell which are able to supply

buildings with power with requirements as low as a few KW’s. The solid oxide

fuel cell (SOFC) is able to be sized to meet low demands such as that from

residential applications or small commercial applications (25 -100KW). For

those applications where the demand for power is as low as a few KW’s the

economic feasibility of use of fuel cells to supply such a low demand are

likely to be border line. The cost of power over the lifetime for fuel cells

decreases for systems supplying larger electrical demands.

The

following web page details how the cost of power from a system is likely to

decrease as the electrical demand increase for a variety of applications http://www.netl.doe.gov/publications/proceedings/96/96fc/fc96/96FC5-2.PDF

107. The

economic viability of installing a fuel cell power plant is greater in those

applications where there is a significant space heating or hot water demand.

The same principle of CHP or cogeneration is applied to fuel cells where much

higher system efficiencies are a result of using heat from the system. Unlike

CHP fuel cell power plants are not sized based upon the heating requirement but

on the electrical requirement. In situation where there is virtually no heating

demand and where the hot water demand may be supplied by other renewable

technology such as solar collectors the effectiveness of the system is reduced.

108.

Increasing the security of supply is one the main benefits of installing a fuel

cell power plant. Building with fuel cell power plants and grid connection

power should be available 99.999% of the year. For industries such as the

electronic industries, those heavily reliant on computing power and hospitals

all of which have a necessity for a very high security of supply the

installation of a fuel cell power plant should be an effective strategy towards

combating the problems associated with power outages. Fuel cell power plants

should be effective for remote towns or villages where outages occur frequently

or for villages where grid connection is problematic. It is likely that the

electronics industry and other industries which require a very high security of

supply of electricity will be willing to pay a higher price for the cost of

electricity. Security of supply from a fuel cell power plant is related to the

quality of the supply network for the supply of natural gas used in the

reforming process to produce. An insecure supply of natural gas will mean an

insecure supply of electricity from a fuel cell power plant.

109. The

security of supply of heat from fuel cell power plant will increase providing

the system is being used for cogeneration.

110. One

of the main factors affecting the viability of a fuel cell power plant is the

availability of natural gas, natural gas is essential for formation of hydrogen

as a feed to the fell cell plant and without a relatively secure supply of

natural gas a fuel cell power plant is not an option. Thus before considering

the installation of a fuel cell power plant it is vital that the quality,

security of supply and cost of natural gas is evaluate for the for the site.

111. The

integration of fuel cell power plant into a building will have some effect of

the architecture of the building. In some cases the fuel cell power plant is

located within a utility room within the building, in other cases it is located

outside. The fuel cell power plant is not a particularly attractive piece of

equipment and it likely to be at least the size of garden shed and is box

shaped. In some cases there may not be space for outdoor installation of the

fuel cell power plant thus it is essential that the space is allocated within a

room for the plant. In buildings where

a fuel cell power plant is retrofitted to an existing building it may be

necessary to make some building alterations in order to accommodate the fuel

cell power plant. It is also essential to consider the requirement of piping

for natural gas the area where the fuel cell is sited; this may mean additional

retrofitting of internal piping.

112. One

of the main benefits of a fuel cell system is the fact that fuel cells are a

very low noise technology. Thus in applications where noise from backup

generator may have been a problem in the past the installation of fuel cell

power plant should be an effective method of combating this. On site emission

from fuel cells are fairly low. There are no other major special

considerations.

113. The

installation cost of a fuel cell power plant is currently a costly undertaking.

Purchase costs are significantly higher than the most efficient generators.

Costs however are comparable with other renewable technologies such as large

number of PV modules.

114.

Energy storage factors. The storage of natural gas may have to be considered if

a reliable source of natural gas is not certain. This will add significant

costs to the installation of a fuel cell power pant.

115. One

main benefits of installing a fuel cell power plant is a reduced cost of